Welcome to Palmer Packaging, Inc.

Offering a Full Line of Industrial Packaging Supplies

Offering a Full Line of Industrial Packaging Supplies

From start to finish, a team of experienced packaging experts will work alongside you to plan your packaging solution.

Our customer service team and a company owned fleet of trucks and drivers will ensure you receive the highest level of service.

Over 35 years of experience helping customers successfully improve their packaging solutions.

Colored Cornerboard also known as V-board on sale with incredible deals Click Here

Bubble & Foam Rolls, Bubble Pouches Foam Corners, Foam Pouches, Loose-fill

Bubble Lined Envelopes, Poly Mailers, Packing List Envelopes, Stayflat Mailers.

Heavy Duty Mailing Tubes, Paper Cores, Snap-Loc Mailing Tubes, White Tubes.

Kraft Paper Rolls, Kraft Paper Sheets, Newsprint Sheet & Rolls, VCI Paper.

Bin Liners, Gusseted Poly Bags, Pallet Covers, Poly Tubing, Reclosable Poly Bags.

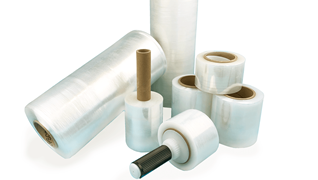

High Performance Shrink Film is lightweight, damage proof, and it easily unwinds from rolls.

Hand & Machines Grade Poly Strapping, Steel Strapping, Strapping Seals & Tools

Palmer Packaging is one of the largest Distributors / Manufacturers in the Midwest with over 35 years in the industry.

Providing over 10,000 SKU’S, along with our own fleet of trucks, we have the ability for next day delivery or just-in-time service.

We also provide fulfillment capabilities, along with stocking programs to provide extra support for our customers.

Contact customer service or your account manager to setup an online account today or complete the Online Account Setup

Palmer Packaging, Inc. is located at 423 S. Grace Street Addison, IL 60101

Hours of Operation Monday - Friday 8 am - 5 pm

Customer Service: (630) 628-6500 Ext. 0 or online form

Equipment Repair: (630) 628-6500 Ext. 227

Copyright © 2023 · All Rights Reserved · Palmer Packaging, Inc.